At 11:00 am on May 29, the first set of V80 78m 2MW land-based typhoon-type wind turbines equipped with towers (wind turbine towers) was completed with Xiamen Shipbuilding Heavy Industry Co., Ltd. for the Fujian Energy Group Co., Ltd. Putian Houhaifeng Tower Project. The car, and successfully shipped out of the company, marked the successful delivery of the Xiamen Shipbuilding Heavy Industry's first wind tower project, filling the gap in the manufacturing of this high-end steel structure in Fujian Province.

It is reported that the wind tower is the first wind tower of Xiamen Shipbuilding Heavy Industry Co., Ltd. and the world's largest wind power equipment manufacturer Danish Vestas Wind Power Company. The tower is 78 meters high, the unit weight is more than 160 tons, the maximum diameter is 4.2 meters, and the maximum thickness is 175 mm. It is the largest wind turbine tower product in China with the largest single machine, high technical difficulty and international leading technology level. With the support of Vestas and the support of Vestas, Xiamen Shipbuilding Heavy Industry successfully completed the production and delivery of the first V80 78m 2MW wind tower. The product quality fully meets the technical specifications and is obtained by Vestas and its owners. High evaluation of the unit.

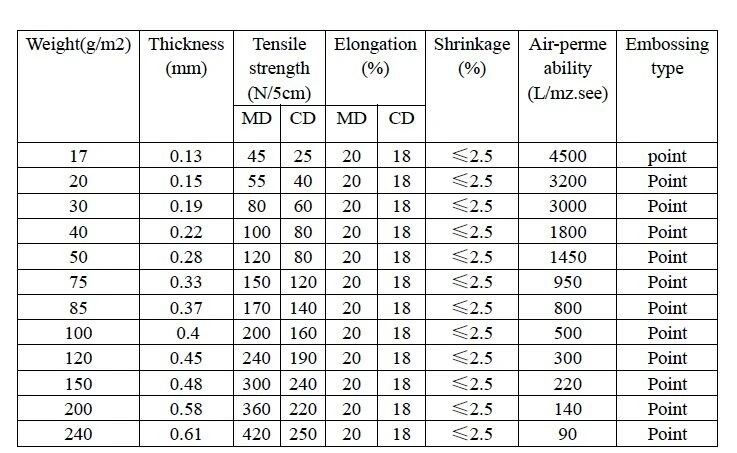

Non Woven Fabric

FY-hengfa nonwoven Fabric series: PET Polyester Spunbond Non woven, Meltblown Nonwoven, Activated Carbon Nonwoven Fabric, Nonwoven Filter Bag,Nonwoven Fabric For Auto Filter.

Such as:

100% PET/PP spunbond nonwoven fabric.

It is similar to filament yarn production. From the chips storage, the polymer is vacuum-fed to a dosing station on top of the extruder. Inside the extruder, it becomes melted and homogenized. Passing a filter system and a spin pump, the melt is fed into the spin beam or spinnerets, which form a curtain of filaments. The filaments are cooled by means of a stream of air in a blowing area, drawn by aerodynamic forces and then transported to the downstream discharge channel. For nonwovens, instead of a further stretching process for filament yarns, the filaments are swirled around and then deposited on the wire mesh belt as a random nonwoven. This web is transferred to a bonding calender that uses heat and pressure to set such physical properties as tensile strength and elongation of the final product. After cooling, the material can be wound.

Product :Spun-bonded Nonwoven

Material :100% polyester

Width :0.15-3.20m.

Specification:1000M-4500M/roll or customized

Weight :10gsm-260gsm

Use :

1. Medical : face mask ,surgical cloth ,bedsheet ,disposable cap , shoose cover .

2. Packing : shopping bag , tablecloth ,wallpaper ,compund packing material .

3. home textile : pillow case ,mattress cover ,linling .

4. Industry : protect the crop from insect .cold weather .filtration materials

Non woven Filter Media,Pet Non Woven Fabric,Activated Carbon Filter Material

Hebei Fangyu Trade Co., Ltd. , https://www.fangyu-filtermedia.com