I. Introduction

Served as an advanced machine tool in modern metal fabrication, the laser cutting machine has been widely used in multiple fields. It shows superior precision and efficiency whether in automobile manufacturing, aerospace, electronic equipment production, fashion design, or architectural decoration.

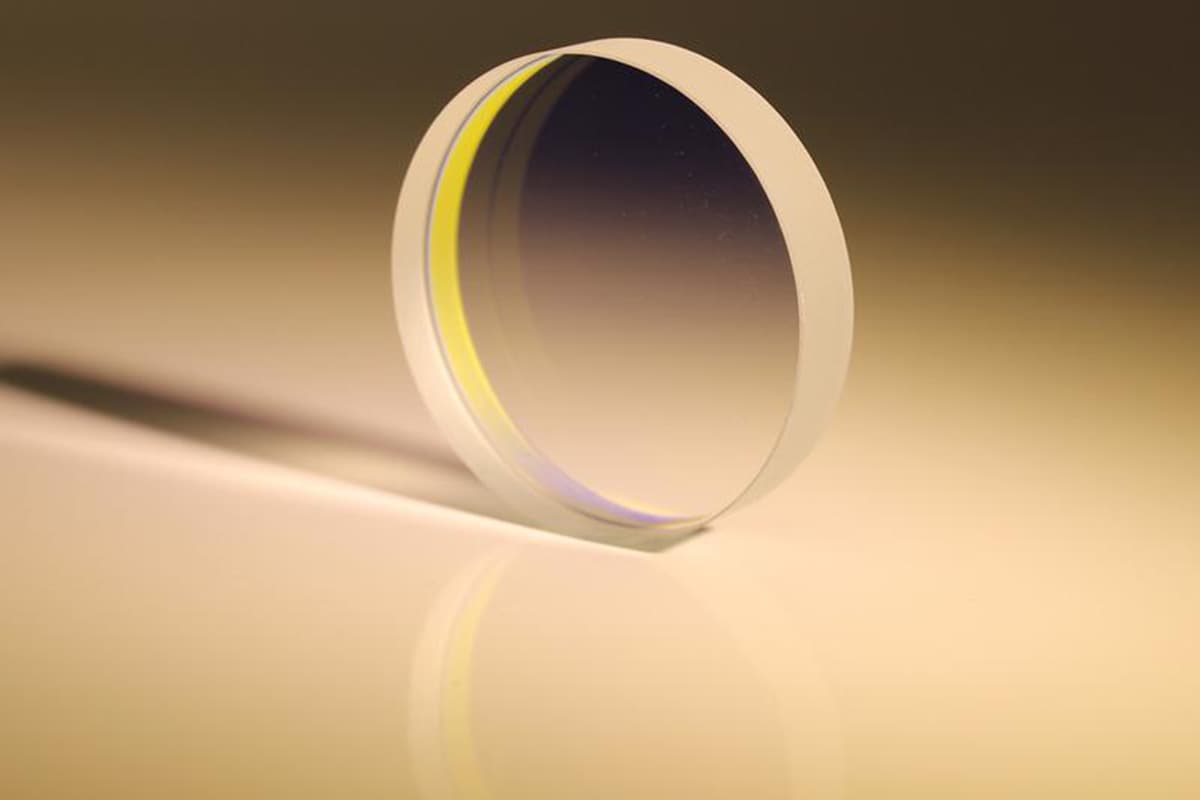

It utilizes a high-intensity laser beam to cut various materials at a high speed and precision, like metals, plastics, wood, and fabrics. Are you curious about how it works?

The laser cutting machine focuses the laser beam onto the surface of the material, making the material melt, vaporize, or burn. Therefore, the precise cutting will be achieved.

Because of its improved efficiency, product quality, processing cost, ability to achieve complex shape cutting, and industry upgrade, the laser cutting machine offers more possibilities and flexibility.

Today, my article mainly aims to talk about the different uses of laser cutting machines in different industries, helping you know the significance of this technology better and its future trends.

II. Key Applications Across Industries

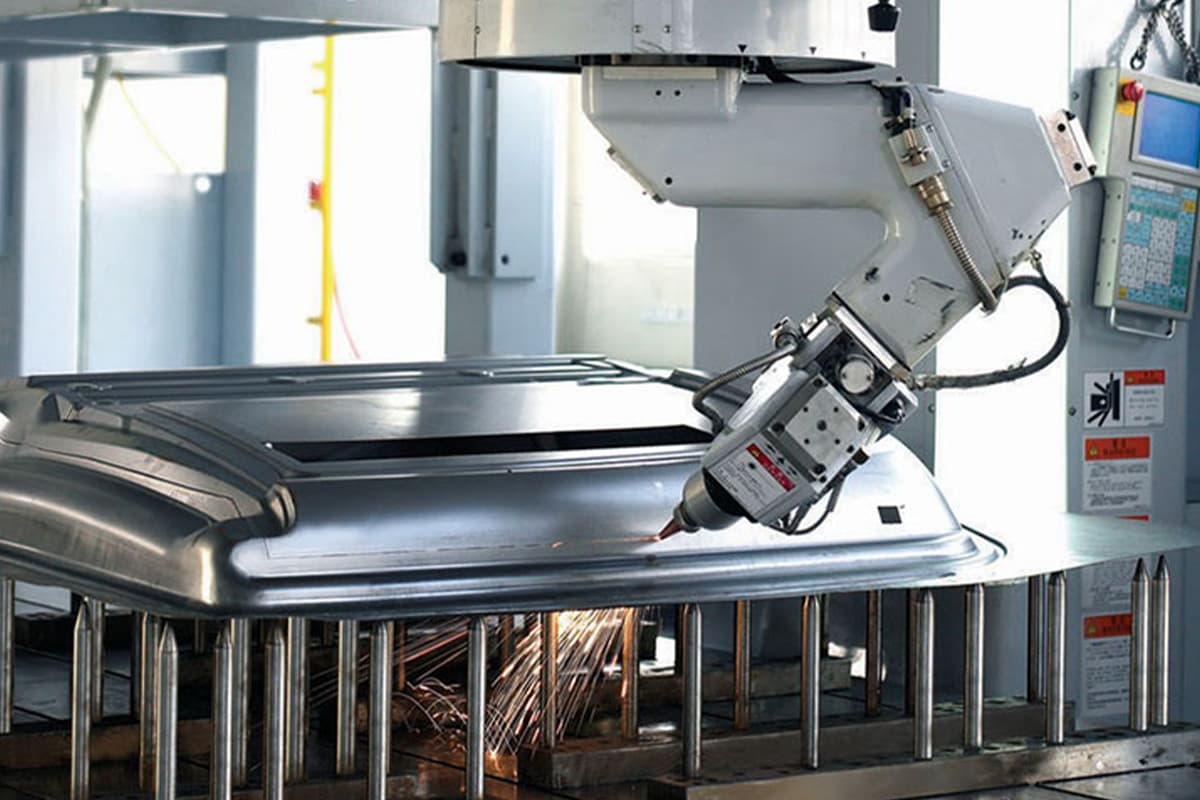

Automotive Industry

Cutting and shaping of metal parts, body panels, and exhaust systems

Laser-cutting machines have become an indispensable tool in the automotive industry. Its features of high precision and high speed make it very suitable for cutting and forming various complex metal parts. For example:

Metal parts cutting:

- Complex shape process:Â the laser cutting machine can cut metal parts with complex shapes efficiently, such as engine brackets, and suspension system components.

- High-precision: due to the minimal diameter of the laser beam, the laser cutting machine can achieve extremely high cutting precision.

- Versatile material:Â the laser cutting machine is suitable for various metal materials to meet the material requirements for different materials, including steel, aluminum, and titanium.

Body panel cutting and forming:

- Large-size sheet processing: the laser cutting machine can cut car body panels with various shapes and sizes to meet the diverse needs of automotive exterior design, especially the body panels with large sizes. With a smooth and consistent cutting-edge line, there is no need to cut the panel twice.

- High-efficient production: the machine tool can greatly enhance production efficiency in that high level of automation.

- Reduce mechanical stress:Â owing to small area of heated zone, the mechanical stress and deformation of material can be decreased, keeping the structural integrity of the body panels.

Exhaust system cutting and welding:

- Precision cutting:Â exhaust system is usually made up of tubes and connectors with complex shapes. The machine tool can cut these parts precisely, ensuring their size accuracy, and connection reliability.

- Welding preparation:Â laser cutting provides a good foundation for subsequent welding processes, reducing welding drawbacks and rework rate.

- Material compatibility:Â laser cutting is access to material with high temperatures like stainless steel and nickel-based alloys, meeting the requirement of an exhaust system for high-temperature resistance and corrosion resistance.

Advantages in precision and speed

Compared with traditional cutting approaches, the laser cutting machine shows prominent advantages in the automotive industry:

High-precision:

- Micron-level precision: laser cutting machine can achieve extremely high cutting precision, and meet the strict requirements for sizes and shapes of auto parts. This is of pivotal importance for automotive accuracy and properties.

- Reduce errors:Â due to non-contact processing, the laser cutting machine helps to avoid the accumulation of blade wear and errors.

High-speed cutting:

- Fast processing: owing to its fast cutting speed, the laser cutting machine can significantly improve the working efficiency and shorten the production cycle. This is very essential for mass-scale automotive manufacturers.

- Adjust instantly:Â the machine tool can adjust the cutting path and parameters according to the drawing design to adapt to different parts processing requirements.

Automation and intelligence:

- Automation production line: laser cutting machine can be used to automatic production line. Thus, there is no need to guard when processing constantly, further improving production efficiency and consistency.

- Intelligent monitor: the modern laser cutting machine is equipped with an advanced monitor and feedback system, which can monitor the cutting process timely, ensuring the cutting quality.

Aerospace Industry

Cutting of intricate shapes for aircraft components

- Wing skins: the laser cutting machine can cut the large, thin-walled wing skins, and makes sure that they can fit the strict requirements for aerodynamics.

- Engine components:Â the complex geometric shapes and high-precise tolerance are required by the turbine blades, combustion chamber, and Other engine components. The machine can be used to satisfy those requirements.

- Internal structural components:Â this machine can be used to produce various reinforcement ribs, frames, and supports inside the airplane, ensuring lightweight and high strength.

Materials used: titanium, aluminum alloys, stainless steel

Titanium:

- Advantages: titanium features high strength, low density, and good corrosion resistance, which is an ideal material for producing aircraft structural components and engine parts.

- Laser cutting characteristics: high power lasers and precise control are needed in the laser cutting process due to the high reflectivity and thermal conductivity of titanium, thus avoiding excessive heat accumulation and oxidation.

Aluminum alloys:

- Advantages: aluminum alloys have the characteristics of lightweight, medium strength, good machinability, and corrosion resistance. This makes it widely used in fuselage and wing structures.

- Laser cutting characteristics: aluminum alloys feature high reflectivity and thermal conductivity. Therefore, a laser (like a fiber laser) with a specific wavelength and an effective cooling system is required to ensure the cutting quality.

Stainless steel:

- Advantages: this material has superior strength, heat resistance, and corrosion resistance, suitable for aerospace components under high temperatures and strict environments.

- Laser cutting characteristics: the cutting speed and assistance gas are needed during the cutting process, thus making sure the smooth cutting edge is without burrs while maintaining the mechanical properties of the material.

Electronics Industry

Precision cutting of circuit boards and electronic components

Laser cutting machine plays a pivotal role in electronics industries, especially circuit board and electronic components cutting. With the increasing miniaturization and complexity of the electronics, traditional mechanical cutting method is unable to meet the precision and efficiency needs.

However, laser cutting machines can achieve fast and precise enough to produce the complex circuit boards and components of smartphones, and tablets, ensuring the common function and properties of the electronic products.

Importance of sharp-edged intricate patterns

When the laser cutting machine generates the chip packaging and connector, the fine lead wire and connection point are needed to ensure a reliable connection between the components.

With the help of a laser cutting machine, the strict requirements for precision and reliability of electronic components can be met. Thus, the operator can obtain sharp edges and intricate patterns.

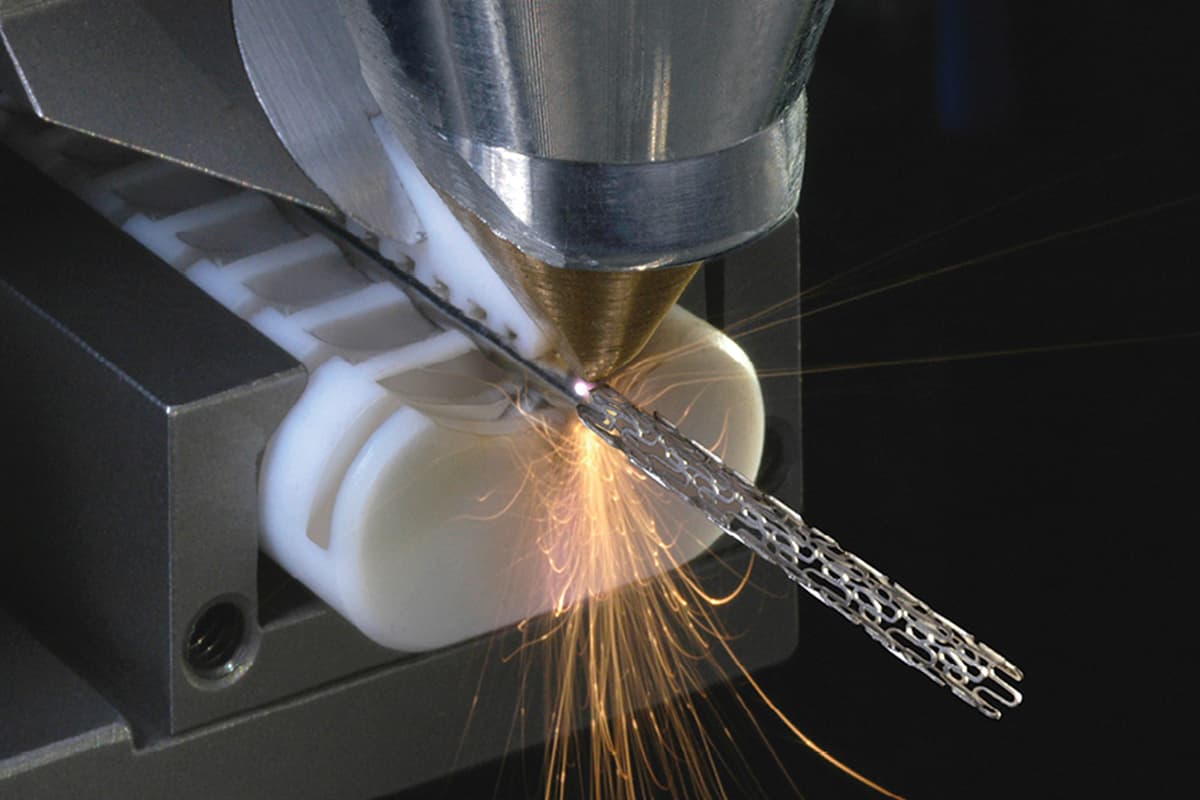

Medical Industry

Surgical instruments:Â laser cutting can be used to generate various surgical instruments with complex shapes and sizes, such as scalpels, scissors, and forceps.

Implants:Â laser cutting machine can also be used to produce various implants, like hip implants, knee implants, and dental implants. It also can precisely cut and form biocompatible materials, such as titanium alloy and cobalt-chromium alloy, ensuring good compatibility between the implants and human tissue.

Medical tubing:Â the laser cutting machine can be used to produce a variety of medical tubing, such as vascular catheter, and urinary catheter. The machine controls the size and shape of tubes, ensuring smooth insertion and operation in the human body.

Jewelry Industry

The laser cutting machine is now widely applied in jewelry, especially the engraving and shaping of precious metals.

Because the laser beam has extremely high precision and controllability, it can cut and engrave finely on precious metals like gold, silver, and platinum, and create complex patterns, delicate textures, and personalized designs.

The jewelry we use nowadays like rings, necklaces, earrings, and other jewelry items are all cut by the laser cutting machine. It is the laser-cutting machine that makes those items unique and memorable.

Furthermore, it can be applied to engrave the letters, patterns, and logos on the surface of the precious jewelry, realizing personalized customization while embossing artistic values.

Construction and Architecture

The laser-cutting machine contributes a lot to steel structures, glass windows, and stone materials. It can cut steel structures of various shapes and sizes, such as beams, columns, and trusses, no need to process them twice.

Also, the glass windows can be cut with delicate shapes and patterns, meeting the requirements for beauty and personalization. What’s more, stone materials like marble and granite can be used for the building's exterior walls and ground paving.

Except for cutting large structural components, laser cutting machines also can be applied to manufacture panels and custom building components. For example, it can cut aluminum plates, and stainless steel plates precisely, and custom decorative panels, ventilation openings, and connectors beautifully.

Advertising and Signage

Customization of letters, logos, and intricate designs

Laser cutting machines can cut various materials precisely like acrylic, wood, and metal in that their high precision and noncontact cutting properties.

Therefore, the enterprise is able to customize brand identity according to the customers’ needs, improving brand recognition and appeal. Besides, the machine tool can be used to make intricate backlit signs, which can be combined with the LED light strip to create eye-catching visual effects.

Use in promotional materials and displays

A laser cutting machine is able to process a large amount of products due to its fast cutting speed and high efficiency. For example, it can be used to make gorgeous paper invitations, personalized business cards, unique packaging boxes, etc.

Agricultural and Fitness Equipment

The laser-cutting machine can be used to generate tractor parts, harvester blades, seeder components, fitness equipment frames, weight plates, and counterweights.

It can satisfy the strict requirements of component size and shapes for agricultural and fitness equipment, ensuring the equipment's stability and reliability.

Environmental Protection and New Energy

Use in the production of solar panels and wind turbines

- Solar panel production:Â laser cutting technology is used to cut silicon wafers without damage, which can improve efficiency and lifespan. Besides, it can cut the patterns of electrodes and connecting wires, optimizing the current conduction path, and improving the overall performance of the solar panels.

- Wind turbine production: the composite materials and metal parts of wind turbine blades can be cut by the machine tool, ensuring the size and shape of blades accurately. Furthermore, a laser cutting machine can also be used to precise welding technology, ensuring the welding point is solid and durable.

Cutting of materials for eco-friendly products

- Renewable material cutting: the machine can be used to cut bio-based plastics (coming from renewable resources), thus reducing the dependence on petroleum-based plastic. Also, recycled paper and cardboard also can be made to produce environmental packaging and products, reducing resource waste and environmental pollution.

- Low carbon material cutting:Â the laser cutting machine can be used to cut lightweight metal materials and composite materials, obviously decreasing the product's carbon emission.

- E-waste recycling:Â laser cutting technology can cut and separate the circuit boards in electronic waste precisely, and extract the precious materials from the metals.

Prototyping and Manufacturing

Rapid prototyping for product development

Rapid prototyping refers to producing the product prototype or model in a short time via laser cutting technology so that the prototype is convenient to test and verify, especially the model with complex geometric shapes and fine structure.

For example, this is significant for electronic products, medical devices, and aerospace components development. Besides, the design team can quickly manufacture and test multiple prototype versions, accelerating the product development cycle.

The designer can modify and optimize the product in a short time, enhancing the product development cycle while improving the market competitiveness.

Mass production of components

Laser-cutting machines are essential for mass-scale production, especially in the industry requiring high precision and consistency.

It is integrated with the automated production line to reduce human intervention errors, make good use of material rate, and even improve the product quality and consistency.

III. Conclusion

In this article, we have explored the extensive applications and significant advantages of laser-cutting machines across multiple domains.

From manufacturing to medical fields, laser cutting machines have dramatically improved the quality of production and processing with their high precision, efficiency, and flexibility.

Whether it's complex metal cutting or delicate medical device manufacturing, laser cutting machines have demonstrated their irreplaceable value.

As technology continues to advance, the range of applications for laser cutting machines will become even more extensive, bringing more innovation and development opportunities to various industries.

Click on the laser cutting machine now to learn more about the high-quality laser cutting machines from ADH Machine Tool Company.

Explore how our advanced technology can enhance your production capabilities and competitive advantage. Don't miss this opportunity; let us help you achieve business success.

Henan Dongfanglong Trade Co.,Ltd , https://www.tjdflpetro.com